Product Introduction

The main body of the dehydrator consists of a fixed ring and an active ring stacked on top of each other, and the spiral shaft passes through it to form a filter device.

The front section is the enrichment section and the back section is the dehydration section. The filter gap formed between the fixed ring and the active ring and the pitch of the spiral shaft gradually decrease from the concentration section to the dehydration section.

The rotation of the spiral shaft not only drives the sludge from the thickening section to the dewatering section, but also continuously drives the dynamic ring to clean the filter gap and prevent clogging.

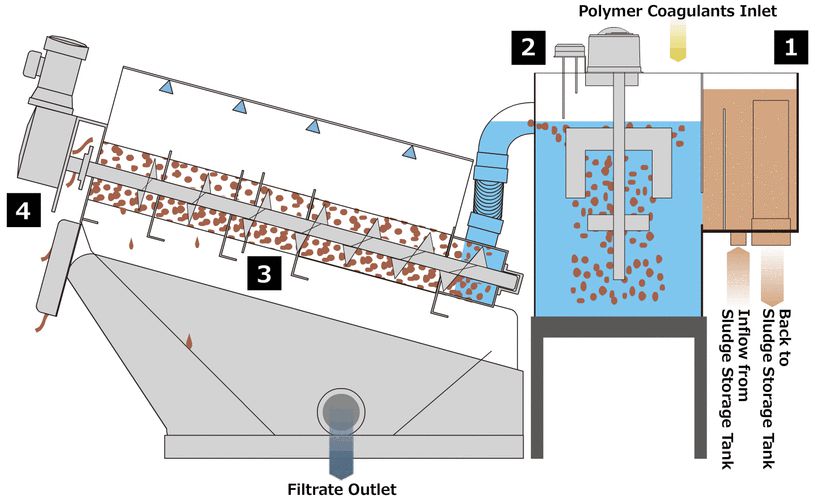

Working principle

The sludge enters the filter cartridge from the inlet and is pushed to the outlet by the spiral shaft rotating plate. The spiral shaft and rotating plate gradually decrease, and the pressure on the sludge continues to increase.

Under the pressure difference, it begins to dehydrate, and water flows out of the filter gap between the fixed ring and the movable ring plate. The device relies on an automatic cleaning function between the fixed plate and the movable plate to clean the gap between the filters and prevent clogging. After full dehydration, the mud cake is discharged from the outlet under the push of the spiral shaft.

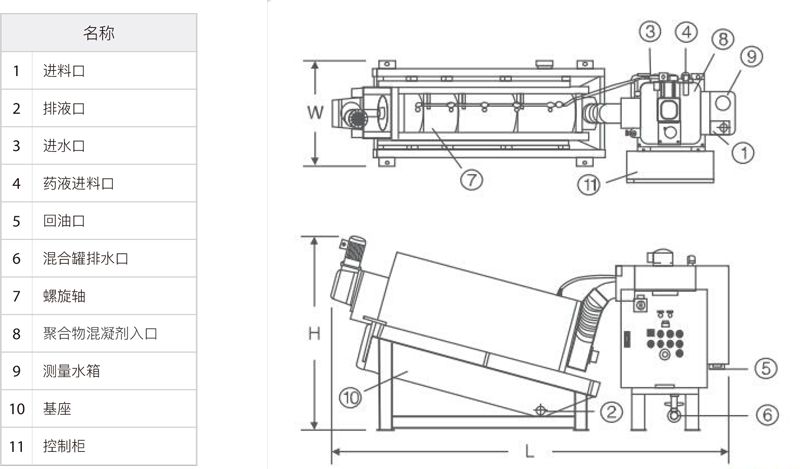

Equipment structure

The sludge dewatering machine is mainly composed of a metering tank, a flocculation stirring tank, a stirring device, a dewatering body, a filtrate tank, a motor, an electric control cabinet and a support. The inlet and outlet of the preparation are equipped with flanges to facilitate field pipe connection.

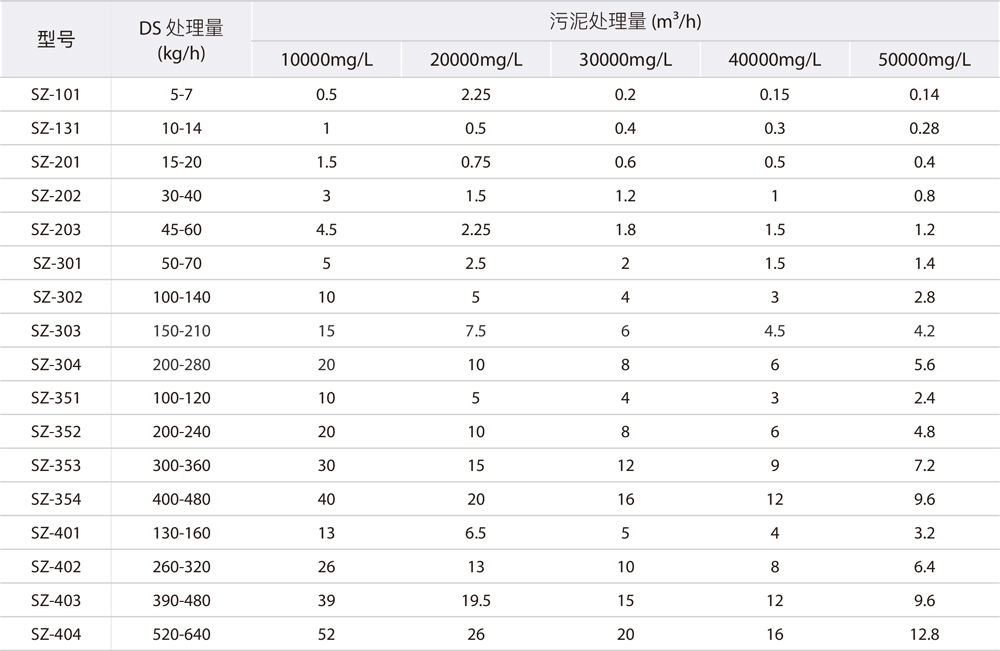

Parameter selection

Size selection