Product Introduction

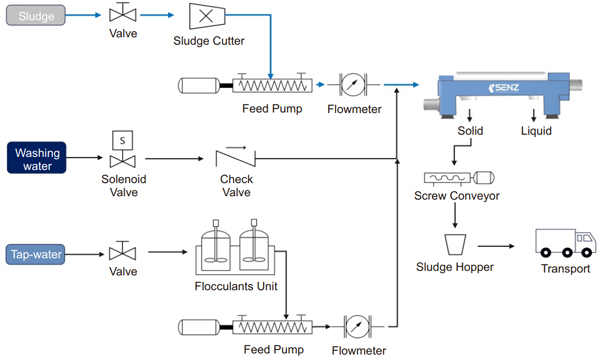

The system is mainly composed of sludge dewatering centrifuge, sludge feeding system, automatic solution preparation and dilution system, dewatering sludge conveying system, fully automated control system and corresponding valve pipeline, which can realize automatic control.

The whole system has a large aspect ratio and a high engine speed. The treatment process includes cutting and crushing, feeding, unloading, conveying sludge, adding flocculants and monitoring the operating status of the entire system. All use PLC+LCD display control system for users to use.

Sludge feed system

The system consists of sludge cutter, pump, electromagnetic flowmeter, solenoid valve, manual valve solenoid valve, pipeline, ultrasonic sludge density analyzer, ultrasonic level meter, separation liquid outlet concentration meter, etc.

The sludge is often mixed with fibers, large particles, hair, etc., and blockage problems often occur when only centrifugal pumps are used. Matching our system can solve this problem.

Flocculant preparation dosing device

The auxiliary equipment is mainly composed of dry powder feeder, dosing screw, mixer, vibrator, agitator, level controller, water supply system, screw dosing pump and control system.

It is suitable for the preparation and dosing of polymer organic flocculant. The dry powder of the agent needs to be directly added to the hopper of the equipment to realize the process of automatic feeding, dissolution, curing, storage, dosing and so on.

It operates automatically and has a 3-channel structure for mixing, curing and storage.

Shaftless screw conveyor

A shaftless screw conveyor is a rotating screw shaft that drives the nut along its axis.

The screw is equivalent to the screw shaft, and the material is equivalent to the nut. When the screw body continuously rotates, the material is also continuously transported. Its helix is a thick ribbon blade driven by the driving end shaft, with no shaft in the middle.

The helix makes contact (slip) with the bottom liner of the inner wall of the casing. The U-shaped conveyor channel is closed, but the upper cover can be opened.

Therefore, it is suitable for the transport of contaminated, odorless, dangerous, bridging and clean materials. It can effectively transport dry, wet, viscous, powdery and rough materials to prevent the effects of clogging and entanglement.

Process flow

The settled sludge is crushed by the sludge cutting machine and transported by the feed pump. The sludge that enters the feed pump flows through the electromagnetic flowmeter into the centrifuge. After centrifuge separation, it becomes a solid and a liquid. The liquid is discharged directly or returned, and the dehydrated sludge is discharged via a shaftless screw conveyor.